![[field:title/]](/images/MC301-L.jpg)

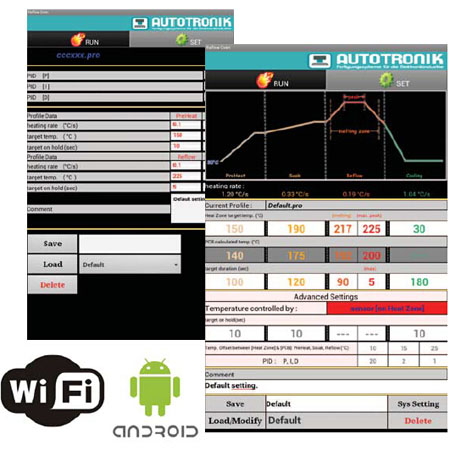

- Real time temperature profile display

- Android system on multi-core CPU platform

- 7" touch screen high resolution LCD display

- Compact design ideal for labs, schools, prototyping and low-volume job shops

- WiFi temperature profile printing and data storage

- Real time close loop PID temperature control for leadfree profile

- Quick Smart programming by rising rate control (degree change per second)

- Infrared and forced convection combine for efficient lead-free reflow Features

PRODUCT INFO

|

BT301 Bench-top / Batch Reflow Oven Dynamic Thermal Profile using a Batch Reflow Oven with Android™ Operating System Match your thermal process specifications for preheat, soak, reflow, and cooling on the first PCB you produce with by using revolutionary new BT301 Batch Reflow Oven. Having the thermal conditions of an inline reflow system in a bench-top unit with a full dynamic thermal process. |

|

|

The BT301 is ideal for product development, prototyping, and small series production. Solder profiles are easily set-up and stored through the control app of the BT301’s exclusive hardware control and Android operating system. The dynamic control system takes care of size and complexity of your assembly and makes it a closed loop process, something only large and costly thermal systems can normally offer.

Real-Time dynamic thermal Control via On-Board measuring device |

SPECIFICATION

| Applicable solder types : | Lead-Free and Leaded |

| PCB holding size : | 350 mm x 240 mm |

| PCB effective heating area : | 250 mm x 200 mm |

| Heating method : | Quartz IR & Forced Hot Air Convection |

| Temperature range : | Ambient - 310 °C |

| Temperature control method : | Real time close loop PID temperature control for lead free profile |

| Warm-up time : | approx. 2 min. |

| Computer control : | Build-in dual core CPU on board computer |

| Display panel : | 7" touch screen high resolution LCD display |

| Temperature control setting : |

Quick smart profile programming by temperature rising rate control (degree change per second) |

| Temperature profile display : | Real time temperature profile display |

| Temp profile printing : | WiFi temperature profile printing |

| Storage : | External data storage via WiFi connection |

| Electrical : | 220 V, Single Phase, 50/60 Hz, 30A in peak, average 15A |

| Power : | 6300W |

| Dimensions : | 690 mm L x 470 mm W x 270 mm H |

| Weight : | approx. 68 Kg |

* We reserve the right to make changes without notice.