BA385E SMT Pick & Place Machine

![[field:title/]](/uploads/allimg/130313/1-1303131K6160-L.jpg)

FEATURES

- High Accuracy, High Flexibility for 0201, SOIC, PLCC, µBGA, CSP, as well as QFP, up to fine-pitch 0.3mm

- Up to 8 000 cph.

- Vision On the Fly Alignment System.

- Bottom Vision Alignment System for fine pitch QFP & µBGA.

- Built in camera system with Auto Smart Fiducial Mark Learning.

- Smart Feeder ID system provide fast set up and easy programming.

- Windows XP Software and Universal CAD Conversion.

- Suitable for small volume production.

SUMMARY

Most Affordable, Most Precise, Full-Vision Placement System

The Autotronik BS-384 provides the versatility, precision, and increased capacity needed for today's most challenging front-end surface mount prototyping, product development, and pilot-production applications. Cognex® vision processing and head-mounted vision cameras allow non-contact, "on-the-fly" alignment of a wide range of standard and odd-form SMDs, from the smallest 0201 devices through CSPs, μBGAs, flip-chips and other components up to 16 mm x 14 mm, including 0.5 mm (20 mil) fine-pitch QFPs. A bottom vision station is used for larger components up to 38 mm x 38 mm. Even fully-loaded with a whopping expanded capacity for up to 128 Smart Tape Feeders, the BS-384 can still handle PCBs up to 14.5" x 13.4".

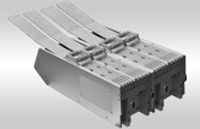

Capacity for Up to Four 32-Port Smart Feeder Bases

Autotronik Smart Feeder Bases can be mounted on all four sides of the BS-384 and each can be loaded with up to 32 Smart 8 mm Tape Feeders. In this arrangement, 14.5" x 13.4" (370 mm x 340 mm) of payload area can be shared by PCBs and waffle trays. Placement area increases to a generous 17.1" x 13.4" (435 mm x 340 mm) with feeder bases mounted on only the front and rear of the system. Click here for feeder arrangements.

Full Catalog of Smart Feeders and Accessories

To go along with the BS-384's large payload capacity, Autotronik offers a full catalog of feeders and accessories to accommodate virtually any type of SMD component packaging, highlighted by our precision tape and stick/tube feeders which utilize our exclusive "Smart Feeder" communication and control technology. The innovative design of our feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. When loading or changing feeders, operators are not forced to remove banks or cassettes of multiple feeders. For additional information on our feeder portfolio, visit our Autotronik Smart Tape Feeder and Smart Stick Feeder Pages.

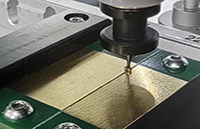

Optional Dispensing Capability Adds Another Dimension of Flexibility

An additional micro-dispensing head, mounted in tandem with the placement head, can be used to apply solder paste and adhesives. Fully-integrated with the BS-300 Series Pick and Place Control Software, the dispensing system allows application of precise solder paste volumes and patterns, and bypasses the need for costly and time-consuming stencil production when trying to meet your time-to-market window. We offer both our patented ATP Digital Dispensing which can apply solder paste and adhesives at dot sizes down to 0.15 mm diameter and a conventional time-pressure dispense system.

DETAILS

Strong and rigid mechanical designBA385 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability.

Strong and rigid mechanical designBA385 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability.  Non-contact Linear Encoder System (Option)By using „Closed Loop“ Servo Motors with non-contact Linear Encoder System, provide extremely high Repeatability and Stability.

Non-contact Linear Encoder System (Option)By using „Closed Loop“ Servo Motors with non-contact Linear Encoder System, provide extremely high Repeatability and Stability.  COGNEX® Alignment System "Vision on the Fly"The BA385 feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA385 assures high-precision placement of the full range of SMDs, from the smallest 0201 devices through CSPs, μBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even odd-form components.

COGNEX® Alignment System "Vision on the Fly"The BA385 feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA385 assures high-precision placement of the full range of SMDs, from the smallest 0201 devices through CSPs, μBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even odd-form components.  Bottom Vision Alignment System (Option)A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed.

Bottom Vision Alignment System (Option)A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed.  Dispenser System (Option)Optional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil.

Dispenser System (Option)Optional stand alone dispenser head for adhesive & solder paste dispensing. Perfect for quick, small volume production without making stencil.  Conveyor System (Option)The optional conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production.

Conveyor System (Option)The optional conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production.  Universal CAD Conversion (Option)Beside the direct input of data by teach-in camera, an optional CAD conversion program is available for directly transfer of CAD generated pick and place data.

Universal CAD Conversion (Option)Beside the direct input of data by teach-in camera, an optional CAD conversion program is available for directly transfer of CAD generated pick and place data.  Auto Tape Feeder (KFTA)The innovative design of KFTA feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. KFTAs are available from 8 mm up to 72 mm tape width.

Auto Tape Feeder (KFTA)The innovative design of KFTA feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. KFTAs are available from 8 mm up to 72 mm tape width.  Universal IC Tube FeederKFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width.

Universal IC Tube FeederKFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width.  Cut Strip Tape HoldersCut Strip Tape Holders is a handy accessory for presenting components that are supplied in short lengths of tape due to their low quantity of usage. It can also prevent the waste of components in sections of tape that are too short to be loaded into tape feeders.

Cut Strip Tape HoldersCut Strip Tape Holders is a handy accessory for presenting components that are supplied in short lengths of tape due to their low quantity of usage. It can also prevent the waste of components in sections of tape that are too short to be loaded into tape feeders.  Feeder Rack2 x FR-48K can be mounted on the front and rear side. Each FR-48K is suitable for 48 x 8mm KFTA Feeders or 40 x 8mm IC-Sticks. 2 x FR32K can also be mounted on the left and right sides of the machine for a total capacity of 160 x 8 mm tape feeders.

Feeder Rack2 x FR-48K can be mounted on the front and rear side. Each FR-48K is suitable for 48 x 8mm KFTA Feeders or 40 x 8mm IC-Sticks. 2 x FR32K can also be mounted on the left and right sides of the machine for a total capacity of 160 x 8 mm tape feeders.  Buffering NozzleThe spring buffering design of Nozzle adjust the placement pressure for different heights of components automatically.

Buffering NozzleThe spring buffering design of Nozzle adjust the placement pressure for different heights of components automatically.  Vision InspectionWith the built-in software, the camera can automatically move and display the image in the computer screen. User can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc.

Vision InspectionWith the built-in software, the camera can automatically move and display the image in the computer screen. User can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc.  Remote Service KitOptional Remote Service Kit allows a remote access to machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center.

Remote Service KitOptional Remote Service Kit allows a remote access to machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center.  Smart Fiducial SystemBeside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark. For more precise placement of fine pitch components, additional Local fiducial recognition is provided.

Smart Fiducial SystemBeside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark. For more precise placement of fine pitch components, additional Local fiducial recognition is provided. MES functions(Option)MES functions, which can achieve intelligent scheduling of production plans, real-time collection of production data, tracking of process flows, quality monitoring and management of equipment status. Through these functions, user can grasp the production status of the workshop in real time, optimize resource allocation, reduce production costs, response speed and product consistency improved.

MES functions(Option)MES functions, which can achieve intelligent scheduling of production plans, real-time collection of production data, tracking of process flows, quality monitoring and management of equipment status. Through these functions, user can grasp the production status of the workshop in real time, optimize resource allocation, reduce production costs, response speed and product consistency improved. CT30(Option)CT30 combines with the higher performance of an LCR meter, it can be compared with higher-level LCR measuring instruments in terms of accuracy, range and speed.

CT30(Option)CT30 combines with the higher performance of an LCR meter, it can be compared with higher-level LCR measuring instruments in terms of accuracy, range and speed.

SPECIFICATION

| Number of Heads(Vision on the Fly): | 1 / 2 |

| Placement rate: |

BA385E1: 4000 CPH(under the optimum condition), 3400 CPH (IPC 9850) BA385E2: 8000 CPH (under the optimum condition), 5500 CP/H (IPC 9850) |

| Feeder capacity (8 mm) without conveyor: | up to 128 Tape Feeders |

| Feeder capacity (8 mm) with conveyor: | up to 64 Tape Feeders |

| IC Tray capacity: | up to 2 Waffle Trays |

| Component Sense: | Vision detection |

| Component Size |

Handled by head camera:- Smallest: 0.6 x 0.3mm - Largest: 16 x 14 mmHandled by fixed Bottom Vision Camera:- Smallest: 0.4 x 0.2 mm (option) - Largest: 150 x 100 mm (option) |

| Resolution: |

X / Y axis 0.005 mm Servo Motor Z axis 0.02 mm Servo Motor |

| Rotation: | 0 to 360° (0,09°/step) Servo Motor |

| Placement Accuracy: |

+/-0.05mm ( Chip components) +/-0.03mm (QFP , uBGA) |

| X-Y Repeatability: | +/- 0.01 mm |

| Placement Area: |

Placement area without conveyor:Max. 435 x 430 mm without Waffle Trays Max. 435 x 270 mm with 1 Waffle Tray Max. 435 x 130 mm with 2 Waffle Trays Placement area with conveyor:Max. 435 x 460 mm without Waffle Trays Max. 435 x 310 mm with 1 Waffle Tray |

| Programming:: | Direct input, Vision teach-in, CAD Access (Option) |

| Main Control: | Industrial PC |

| Weight: | 690 kg |

| Power: |

220 V / AC BA385E1: 2400W BA385E2: 2400W |

| Pressure: | 75 psi (5.5 bar), 200 L/min |

| Machine Size: | 1400 x 990 x 1700 mm (W x D x H) |

* We reserve the right to make changes without notice.

Features & Optional Accessories

|

|

|

|

| Exceptional Placement Area and Feeder Capacity | Head-Mounted Vision Camera for “On-the-Fly” Alignment | Bottom Vision Camera for Fine-Pitch QFPs, μBGAs, CSPs (with BV38, option) |

|

|

|

|

| Optional Dispense Head Applies 6 mil Dot | High-Precision Ball-Screw X-Y Drive Mechanism | Powerful Windows®-based control software |

|

|

||

| Automatic datum point recognition of PCBs, which is particularly useful when combined with the inline conveyor system |